When an equipment frame is bonded to metal conduit, it acts as the equipment’s grounding electrode. This crucial connection ensures proper grounding and minimizes electrical hazards. By understanding the role of this bond, you can maintain a safe electrical environment. Let’s explore the significance of this bond and its implications for electrical equipment safety.

When an Equipment Frame is Bonded to Metal Conduit, it Acts as the Equipment Guardian

Have you ever wondered why equipment frames are often bonded to metal conduits in various electrical installations? Well, when an equipment frame is bonded to metal conduit, it acts as the equipment guardian, providing crucial protection and ensuring the safety and functionality of the electrical setup. Let’s delve into the importance of this bonding and how it serves as a vital element in electrical systems.

The Purpose of Bonding Equipment Frame to Metal Conduit

Firstly, let’s understand why bonding the equipment frame to a metal conduit is necessary. This bonding serves multiple purposes, with safety being the primary concern. When electrical equipment is installed, it is crucial to establish a grounding system to prevent electrical shocks, fires, and other hazards. By bonding the equipment frame to metal conduit, a reliable grounding path is created, ensuring any electrical faults are safely directed away from the equipment and users.

1. Enhancing Electrical Safety

One of the key reasons for bonding the equipment frame to metal conduit is to enhance electrical safety. In the event of a fault or surge, the metal conduit provides a low-impedance path for the current to flow, effectively grounding the equipment and preventing any potential harm to individuals nearby. Without this bonding, the risk of electric shock and equipment damage significantly increases.

2. Minimizing Electromagnetic Interference

Another benefit of bonding the equipment frame to metal conduit is the reduction of electromagnetic interference (EMI). Electrical systems can generate electromagnetic fields that may interfere with nearby equipment or communication signals. The metal conduit acts as a shield, containing these electromagnetic waves and preventing them from causing disruptions or damage.

How the Bonding Works

Now that we understand the importance of bonding the equipment frame to a metal conduit, let’s explore how this process works. The bonding is typically achieved using bonding jumpers or straps that establish a direct connection between the equipment frame and the metal conduit. These jumpers ensure a continuous conductive path, allowing any fault current to safely dissipate through the conduit.

1. Bonding Jumpers

Bonding jumpers are flexible metal straps or wires that connect the equipment frame to the metal conduit. These jumpers are designed to withstand electrical currents and ensure a reliable bond between the two components. By securely fastening the jumpers in place, a low-resistance path is established, enabling effective grounding and fault protection.

2. Conductive Connections

Ensuring a conductive connection between the equipment frame and metal conduit is crucial for proper bonding. The connection points must be clean and securely fastened to maintain a continuous path for electrical currents. Any corrosion or loose connections can impede the effectiveness of the bonding and compromise the safety of the electrical system.

Impact on Equipment Performance

When an equipment frame is bonded to a metal conduit, it not only enhances safety but also has a significant impact on the performance of the electrical equipment. The presence of a reliable grounding path improves the overall efficiency and longevity of the equipment, ensuring optimal operation and reducing the risk of malfunctions or downtime.

1. Equipment Protection

By acting as the equipment guardian, the bonded metal conduit helps protect electrical devices from damage caused by electrical faults or surges. The grounding provided by the conduit ensures that any excess current is safely diverted away from the equipment, preserving its integrity and preventing costly repairs or replacements.

2. Stability and Reliability

Having a stable and reliable electrical system is essential for any application. When the equipment frame is bonded to a metal conduit, the system’s stability is enhanced, reducing the likelihood of voltage fluctuations or erratic behavior. This, in turn, improves the reliability of the equipment and ensures consistent performance over time.

Ensuring Compliance with Standards

In the realm of electrical installations, compliance with industry standards and regulations is paramount to ensure the safety and functionality of the equipment. Bonding the equipment frame to a metal conduit is often a requirement outlined in electrical codes and standards to maintain a secure electrical system.

1. National Electrical Code (NEC)

The National Electrical Code (NEC) provides guidelines and regulations for electrical installations in the United States. It includes specific requirements for equipment bonding to metal conduits to safeguard against electrical hazards and ensure compliance with safety standards. Adhering to the NEC standards is crucial for maintaining a safe environment and preventing code violations.

2. International Electrotechnical Commission (IEC) Standards

Internationally, the International Electrotechnical Commission (IEC) sets standards for electrical systems and equipment across various countries. These standards often include provisions for equipment bonding to metal conduits to establish proper grounding and minimize risks associated with electrical installations. Complying with IEC standards is essential for ensuring global compatibility and adherence to best practices in electrical engineering.

In conclusion, when an equipment frame is bonded to a metal conduit, it acts as the equipment guardian, providing essential protection and grounding for electrical systems. This bonding not only enhances safety and minimizes risks but also improves the performance and reliability of the equipment. By understanding the importance of this bonding and ensuring compliance with industry standards, electrical installations can operate efficiently and securely. Remember, the next time you see equipment frames bonded to metal conduits, it’s not just a connection—it’s a safeguard for a safer and more reliable electrical setup.

Stay informed, stay safe, and keep your electrical systems grounded!

SHORTS – WHY WE BOND (Neutral & Ground) Explained in 3 Minutes

Frequently Asked Questions

What function does an equipment frame serve when bonded to metal conduit?

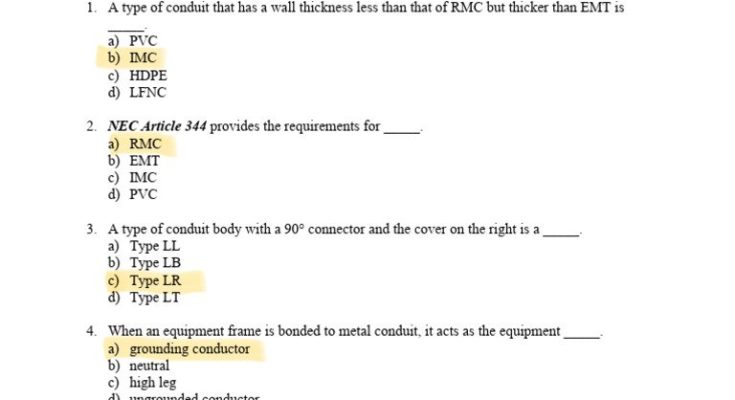

When an equipment frame is bonded to a metal conduit, it acts as a grounding conductor, providing a path for fault currents to flow safely to the ground to prevent electrical shocks and protect the equipment.

How does bonding an equipment frame to metal conduit enhance electrical safety?

Bonding an equipment frame to metal conduit ensures that any stray currents or leakage in the electrical system are safely directed to the ground through the conduit, reducing the risk of electric shock and fire hazards.

Why is it important for equipment frames to be bonded to metal conduit in electrical installations?

By bonding equipment frames to metal conduit, the risk of voltage potential difference between different components is minimized, ensuring the electrical system operates in a safe and reliable manner.

Final Thoughts

When an equipment frame is bonded to metal conduit, it acts as the equipment grounding conductor. This ensures proper grounding for the equipment and creates a safe electrical pathway for fault currents to return to the source. Bonding the equipment frame to the metal conduit helps to prevent electrical shock hazards and protects both the equipment and individuals working with it. In summary, the bond between the equipment frame and metal conduit is essential for maintaining electrical safety and functionality.